Structure design and drying characteristics of paddle dryer

1, structural design

The paddle dryer is a new type of energy-saving dryer with a jacket on the outside. Two vane shafts rotate inside each other, and the shaft and the blades are hollow. The heat medium is fed into the shaft, the vanes and the jacket through the swivel joint and the flange. The whole body, shaft and blade can transfer heat and dry materials. The blades on the shaft are radially arranged in a spiral, which realizes the stirring and conveying of the paste material. When the axis is symmetrical, the blades are interlaced to each other, and the materials are cleaned from each other. The outer edge of each blade has an auxiliary blade, and the outer end of the blade has a small distance from the casing. The function is to eliminate the dead angle and fully stir the material to make the axial movement of the material close to the piston flow. Both the shaft and the blade are pressure members, and the thickness design should consider wear resistance and pressure. The layout of the blade should take into account the transport and self-cleaning action of the viscous paste material, and also ensure that it cannot interfere in the hot state. The heat carrier can be hot water, hot oil or water vapor, and the temperature range is 50-320 ° C, and the pressure range is 0.4-1.5 MPa.

2, drying characteristics

The general drying process of the paddle dryer: the wet material enters from the feeding port and rotates in the two-axis mutual rotation, conduction heating, and drying to the discharge port. The material vapor is taken by the hot air introduced from the hot air inlets at both ends to the upper vent. The whole process is completed once from the feed to the dry discharge.

The dryer features as follows

(1) Wide applicability, can be used for drying of the following materials in chemical, pharmaceutical, food, brewing, metallurgical and other industries: organic materials, inorganic materials, viscous materials, non-stick materials, granular materials, powder materials, and The amount of moisture can be dried;

(2) The shaft, the blade and the shell can all transfer heat, the drying area is large, the drying speed is fast, the thermal efficiency is more than twice that of the ordinary drying equipment, and the thermal efficiency can reach more than 80%;

(3) Various operation methods, which can be operated intermittently or continuously, can be pressurized or vacuum operated, and also suitable for heat sensitive materials;

(4) The shaft speed can be adjusted (generally 3~25r/min, peripheral speed 0.03~1.5 m/s), which can control material drying temperature, drying time, final moisture content, output, etc., and the material is evenly mixed and evenly dried. ;

(5) Because it is conduction heating, the amount of gas required for drying is small, energy saving is remarkable, 40% steam is saved compared with similar products, and electricity saving is 30%;

(6) There is very little dust entrainment, and the discharged gas is easy to handle, and the subsequent processing equipment such as the powder object collection system and the material vapor recovery system have small load, or may be omitted;

(7) The structure of the paddle is special, and the heating surface has self-cleaning function;

(8) When an inert gas is used as the carrier, the organic solvent can be recovered;

(9) The rotation of the two shafts at low speed, the amount of wear of the blades and the shaft is small;

(10) There are few wearing parts, and the operation and maintenance cost is low. Only the inner static ring of the bearing bush and the rotary joint is a wearing part.

As a new type of energy-saving dryer, the paddle dryer is widely used in the background of energy saving and environmental protection because of its energy saving, good operating environment and wide applicability. Moreover, the equipment manufacturing trend is becoming larger and higher. The development of the finish.

Therefore, the market prospects for paddle dryers are broad and require intensive research and design. In this paper, the finite element method is used to analyze the stress levels of the main components of the dryer for various designs of the specific design, in order to provide some suggestions for the optimization of the strength of the dryer.

Stress calculation

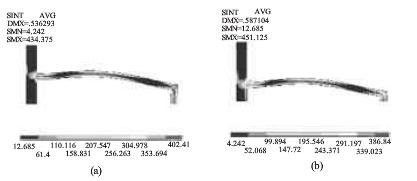

In view of the complexity of the structure and working conditions of the dryer, this paper uses the large finite element software ANSYS to calculate the stress distribution of the main part of the equipment and the hollow blade, and then evaluate the strength of the equipment. To this end, combined with the actual initial design dimensions and structural features, the dryer body uses a three-dimensional mechanical model, while the blades use an axisymmetric two-dimensional model.

The design pressure and design temperature of the dryer were 1.3 MPa and 180 °C, respectively. The boundary condition of the main body of the dryer: select either side as the symmetrical boundary condition, the other side of the head period coupling constraint and the end force load; the upper end face limits the normal displacement of the end face; the pressure is applied to the pressed part of the whole structural model; Close the symmetry boundary. Dryer blade boundary conditions: The lower section of the central axis and the lower section of the blade are symmetric boundaries, and the end face force load is applied to the section on the central axis; the pressure load is applied correspondingly at the pressed part.

The stress of the main structure of the dryer is larger: the connection between the support pipe and the jacket; the greater stress of the hollow blade is the connection between the blade and the central axis (on the blade).

| Structure | Stress classification | Stress value | Assessment | Result |

| Dryer body | Partial film stress | 176 | <1.5*125 | Failed |

| Primary + secondary stress | 524.9 | > 3*125 | ||

| Hollow paddle (a) | Partial film stress | 43 | <1.5*125 | Failed |

| Primary + secondary stress | 422.5 | > 3*125 | ||

| Hollow paddle (b) | Partial film stress | 42.31 | <1.5*125 | Failed |

| Primary + secondary stress | 404.3 | > 3*125 |

Optimization design of paddle dryer

In view of the unsatisfactory strength of the above initial design structure, some improvements are needed. At the same time, due to the complicated structure of the main body of the dryer and the large number of design parameters, it is necessary to study the degree of the inferiority of the influence of these parameter changes on the equipment stress, and finally provide some suggestions for the optimization design of the strength of the dryer.

1. Optimized design of the main structure of the dryer

By comparing the second and third schemes with the scheme one, it can be found that the scheme 2 is the best, that is, increasing the wall thickness of the support pipe is more effective than increasing the wall thickness of the jacket to effectively improve the main body strength of the dryer.

2. Improved design of hollow blade of dryer

The improvement scheme and finite element calculation results of the two hollow blade structures of the dryer can be found that the increase of the thickness of the blade plays a major reinforcing role, and the thickness of the central axis can be reduced within a certain range.

In conclusion

As a new type of energy-saving dryer, the hollow blade dryer has been paid more and more attention, and the application field has expanded rapidly. It has prompted designers to deeply study the optimization design of the dryer structure and further develop the reliability, rationality and economy of the equipment.

In this paper, the finite element method is used to analyze the stress intensity of the main components of the hollow blade dryer, such as the main body and the blade section, and the optimization design of the equipment strength is preliminarily carried out. Some useful suggestions are put forward:

(1) Increasing the wall thickness of the support pipe to increase the wall thickness of the jacket can more effectively improve the strength of the dryer body.

(2) The increase in the thickness of the blade plays a major reinforcing role, and the thickness of the central axis is correspondingly reduced under the permission conditions.